Calibration Services

ITL LABS Pvt.Ltd. Delhi has been a leader in India for the Testing of for 25 years. Opened Branch at Indore, Now offering solutions to customers in Calibration.

ITL LABS Pvt.Ltd. Indore is a NABL accredited calibration laboratory as per international standard IS/ISO/IEC 17025. Our calibration laboratory have its precision measuring instruments facilitates for THATMAL, PRESSURE & VACUUM, MASS, VOLUME, RPM & TIME Calibration.

A highly skilled staff ensures accurate calibration & measurement of instruments. We offer our valued customers the highest quality services that enable them to achieve better process control and quality systems.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

We help you ensure your products meet proprietary criteria and industry or government regulations, identify if products and shipments contain non-standard or non-compliant components and materials and minimize defective products, reduce customer complaints and late shipments. Our independent inspection services protect your business interests, help you manage your risk, and ensure quality products are manufactured and delivered to their final destination at the specifications of the customer. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Our industries include | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Calibration Services and Inspection

Development of new products

| Development of new products |

Over the years, the R&D activities of ITL Labs have been expanded covering different areas of materials. The present activities of research involve: |

|

| The areas in which R&D is being actively pursued are quite varied from polymers, health care, waste utilization to food, agricultural and herbal products. |

| Thrust Areas |

|

| Facilities Available |

|

| Polymers |

| In view of their versatile properties, / polymers are called wonder materials. They have substituted traditional materials such as metal, glass, wood & concrete either fully or partially in most of the end use applications. Material Science Division has always been involved in contemporary research and has developed, modified & commercialized a number of processes over the years. The main areas in which MSD deals are: |

|

Analysis & Testing of Variety of Materials

| Analysis & Testing of Variety of Materials |

| Materials Analysis Laboratory Services include: |

|

R & D Specialized Services

Technical Consultancy

| Technical Consultancy |

Herbal Products

|

| Process Modification |

| ITL Labs can provide help in modification of existing processes for: |

|

| Facilities Available |

| Instrument laboratory ITL Labs has a wide range of state of the art equipment for characterization of polymers, which includes: |

| Thermal Analysis Instruments |

|

| Instruments For Rheological Properties |

|

| Pilot Plant ITL Labs has a rich pilot plant facility housing various processing equipment, which include: |

|

| Others ITL Labs has a rich pilot plant facility housing various processing equipment, which include: |

|

Study of Microbiological

| Microbiological Studies |

Thrust Areas

|

| Product Quality Inspection And Certification |

|

| Detection Of Pathogens |

| Name Of The Pathogens |

|

| Protocols /Techniques Followed |

|

| Enumeration Of Spoilage Microbes |

| Micro-organisms are ubiquitous in nature. Quality and shelf life of any product depends on presence and nature of micro-organisms contained in it. Under favourable conditions these micro organisms proliferate and result in loss of product quality. Microbiological monitoring is an essential part of quality control. ITL labs plays an important role in testing and certification. |

| Test Parameters |

|

| Residual Anti-Microbial Substances |

| Food-producing animals are given antimicrobial drugs for prevention of disease and for their well being. The residues of these antimicrobial drugs remain in and on the body of the animals. |

| Following anti-microbial residues are being tested at ppb levels using ELISA techniques. |

|

| Bacterial Enterotoxins |

| Bacteria produces Enterotoxins as a part of their metabolic activities. Some of them are heat labile while others are heat stable in nature. Even severe food processing treatments can not eradicate these toxicants and may result in food intoxication. |

| SRI undertakes testing of the following Enterotoxins in food and food products. |

|

| Mycotoxins |

| Mycotoxins are carcinogenic, highly toxic metabolites of fungi like Aspergillus, Fusarium and Penicillium. They are toxic even in trace quantities |

|

| Monitoring of Indoor Air |

| ITL labs carries out air-monitoring studies for presence of microbes. Services are provided in the following areas |

|

| Preservative Efficacy |

| Nanotechnology In pharmaceutical, herbal and cosmetic formulations, various anti-microbial substances are added to arrest microbial activity and extend shelf life of the products. The effectiveness of these substances are evaluated as per USP protocols. Selection of challenge micro-organisms include gram positive and gram negative bacteria, spore formers, yeast and fungi. |

| Disinfection Efficacy |

| The Phenolic and non-phenolic type disinfectants are being tested for their germicidal value as per National and International protocols. |

Study of Environment

| Environment Studies | |||||||||||||||||

| |||||||||||||||||

| ITL Labs provides a wide range of services including : | |||||||||||||||||

|

Calibration and Certification in Analytical method

| |||||

A set of operations, performed in accordance with a definite procedure, that compares the measurements performed by an instrument to those made by a more accurate instrument or a standard for the purpose of detecting and reporting, or by adjustment, errors met in the instrument tested. Purpose of Calibration To ensure readings from an instrument are consistent with other instruments and to determine the accuracy of the instrument i.e. that it can be trusted for its observed/displayed measured value. | |||||

| The value of calibration for industry | |||||

| |||||

| What is Traceability ? | |||||

| Property of the result of a measurement or related to stated references, usually national or international standards, through an unbroken chain of comparisons all having stated uncertainties. | |||||

| Why measurements must be Traceable ? | |||||

| |||||

| Uncertainty- How accurate are your measurements ? | |||||

| It is a measure of the quality of a measurement & provides the means to assess & minimize the risks and possible consequences of poor decision. (A measurement with a stated uncertainty can be compared to others) (Measurements are traceable when they can be related to recognised measurement system through an unbroken chain of comparisons each with stated uncertainties.) | |||||

| Calibration Interval-Validity Period. | |||||

| Validation is usually nominal maximum period between two successive calibrations. The validity period is generally considered to be maximum appropriate, provided | |||||

| |||||

| Adequate records of the test data must be maintained over a period of time to draw support for extension of validity period. | |||||

| Calibration Measurement! How ? | |||||

| |||||

| ITL Labs Calibration Laboratory provides valid and accurate measurements using updated standards having unbroken chain of traceability to National and International Standards. | |||||

| ITL Labs- CALIBRATION SERVICES | |||||

|

Analytical Method Development

| |||||||||||||||||||

The Experts of ITL Labs conduct specialised training programmes on behalf of various organisations in different fields of Science and Technology. The scientists also undertake several projects related to social sectors wherein extensive training is provided to the various agencies for the development of rural sectors. | |||||||||||||||||||

| Training Needs | |||||||||||||||||||

| Training needs of the ITL Labs staff are assessed on a continuous basis. The assessment is done at individual as well as organisational level. An annual Training Calendar is prepared at the beginning of the Financial Year, through personal discussion with the Laboratory Incharge, Divisional Head and the Director. The feedback is provided by the Trainee and the Divisional Head reports about the effectiveness of the training. | |||||||||||||||||||

| Induction Training Programmes | |||||||||||||||||||

| Under Induction Training Programmes, all the new employees in the Institute are provided training. Every new employee is put under a senior colleague capable of providing support, advice and help to provide certain basic inputs that would help him/her in functioning effectively. Orientation programmes are also carried out for new employees. | |||||||||||||||||||

| Specialised Instrumentation | |||||||||||||||||||

| Depending upon aptitude, employees are also imparted training on operating the sophisticated instruments like FTIR, GC, HPLC, GCMS , ICP,AAS etc. | |||||||||||||||||||

| External Training | |||||||||||||||||||

| From time to time ITL Labs sends employees to attend specialised courses/workshops to attain proficiency in their respective fields. The employees are also encouraged to attend seminars/conferences etc to update their knowledge. | |||||||||||||||||||

| Practical Training To Students From Academic Institutions | |||||||||||||||||||

| ITL Labs has memorandum of understanding signed with various Universities and Institutes of Technology in the country for exchange of research programmes and joint research projects. ITL is associated with various academic Institutions all over India for providing training facilities to their graduate and post graduate students. The students are required to complete a project and prepare a report as part of the practical training/project, which is an integral part of their curriculum. |

Thing Potions?

What are Dashboard of Things Potions?

Test Microbiology in Market

Microbiology Testing Technologies Market - Global Industry Analysis, Trends and Forecast 2016 - 2023

Microbiological tests comprise the studies of various types of microbial products such as bacteria, yeast, fungus, viruses and their effects on patient population. These products provide an array of experimental approaches (i.e. synthesis and sequencing) to either modify a biological system or mimic it. Microbiology testing technologies enables to examine presence of pathogenic micro-organisms or their metabolites by means of micro-biology techniques.

Microbiological testing technologies have wide area of application in the field of healthcare (e.g. syphilis, tuberculosis, gastrointestinal tests), food industries (e.g. food safety testing) and environmental industries (e.g. environmental testing). The foremost objective to use microbiology testing technologies is to understand human diseases (e.g. cancers, genetic diseases and others) better than before and identify new molecular targets to facilitate drug discovery.

Rising incidences of infectious and sexually transmitted diseases globally will drive the market of microbiology testing. In addition, technological advancements have made microbiology tests faster and more accurate that increases the use of these tests and hence drives the growth of the market. Additionally, wide application areas of microbial test in the field of healthcare, energy and environment will further increase the uptake of nicrobiology technologies hence drives the market growth of microbiology testing technologies.

Moreover, introduction of new tests by key players will further drive the growth of microbiology testing technologies market globally. For example, in February 2012, BioControl Systems launched a new Non-O157 Shiga Toxigenic E.coli (STEC) test. This test is different in that it has advanced the techniques associated with food microbiology and molecular technology. More importantly, it aids in the quicker and more efficient detection of the non-O157 serotype of E.coli. Thus, such innovative launches by key players attract new customers to use microbiology tests and technologies and will consequently drive the growth of the market. However less specific actions of microbiology tests will restrain the growth of microbiological testing technologies market. In addition, insufficient regulatory framework and guidelines and high cost of microbial products will restrain the growth of microbiology testing technologies market.

The market of microbiology testing technologies can be segmented into:

By Technology

-Rapid microbiological methods

-Antibiotic resistance detection

-Bio-fuel technology

By End Users

-Clinical application

-Non clinical application

Geographically, the most dominant region in the global microbiological testing technologies market is North America. The region’s leading position can be mainly ascribed to the presence of key players headquartered and/or operational in this region; many of these players offer an expansive portfolio of microbiological tests and technologies. Europe, which is the second-largest regional market for microbiology testing technologies, also holds promising opportunities.

Consistent advancements in the field of molecular diagnostic tests, such as the genetic probe test, for instance, coupled with positive initiatives by governments for the development of the field of microbiology will help stimulate advances in microbiology technologies. This will prove beneficial for the market’s growth in Europe. For example, in March 2012, Abbott Laboratories obtained the CE Mark approval in the European Union, which allowed it to market PLEX-ID. This instrument features advanced molecular diagnostic technology which makes it suited for detecting and identifying a broad range of microbes. With such new launches and approvals by government authorities, the uptake of microbiology testing technologies will eventually increase and lend support to the market’s growth.

In addition to traditional markets, countries in South-East Asia along with India and China are regarded as rapidly developing markets for microbiological testing technologies because of increasing acceptance of microbiology tests and technologies by biotechnology companies and others.

Various key players actively participating in this market are Bio-Rad Laboratories, Inc., Abbott Laboratories, Gen-Prove, Inc., Agrivida, Inc., Agilent Technologies, Inc., Biosearch Technologies, Renewable Energy Group, Inc., ATG: biosynthetics GmbH, Torrey Pines Scientific, Inc., PSS Precision System Science, BioControl Systems and others.

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

About Us

Transparency Market Research (TMR) is a global market intelligence company providing business information reports and services. The company’s exclusive blend of quantitative forecasting and trend analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyze information.

TMR’s data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With extensive research and analysis capabilities, Transparency Market Research employs rigorous primary and secondary research techniques to develop distinctive data sets and research material for business reports.

The market of microbiology testing technologies can be segmented into:

By Technology

-Rapid microbiological methods

-Antibiotic resistance detection

-Bio-fuel technology

By End Users

-Clinical application

-Non clinical application

Geographically, the most dominant region in the global microbiological testing technologies market is North America. The region’s leading position can be mainly ascribed to the presence of key players headquartered and/or operational in this region; many of these players offer an expansive portfolio of microbiological tests and technologies. Europe, which is the second-largest regional market for microbiology testing technologies, also holds promising opportunities.

Consistent advancements in the field of molecular diagnostic tests, such as the genetic probe test, for instance, coupled with positive initiatives by governments for the development of the field of microbiology will help stimulate advances in microbiology technologies. This will prove beneficial for the market’s growth in Europe. For example, in March 2012, Abbott Laboratories obtained the CE Mark approval in the European Union, which allowed it to market PLEX-ID. This instrument features advanced molecular diagnostic technology which makes it suited for detecting and identifying a broad range of microbes. With such new launches and approvals by government authorities, the uptake of microbiology testing technologies will eventually increase and lend support to the market’s growth.

In addition to traditional markets, countries in South-East Asia along with India and China are regarded as rapidly developing markets for microbiological testing technologies because of increasing acceptance of microbiology tests and technologies by biotechnology companies and others.

Various key players actively participating in this market are Bio-Rad Laboratories, Inc., Abbott Laboratories, Gen-Prove, Inc., Agrivida, Inc., Agilent Technologies, Inc., Biosearch Technologies, Renewable Energy Group, Inc., ATG: biosynthetics GmbH, Torrey Pines Scientific, Inc., PSS Precision System Science, BioControl Systems and others.

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

About Us

Transparency Market Research (TMR) is a global market intelligence company providing business information reports and services. The company’s exclusive blend of quantitative forecasting and trend analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyze information.

TMR’s data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With extensive research and analysis capabilities, Transparency Market Research employs rigorous primary and secondary research techniques to develop distinctive data sets and research material for business reports.

Today Pharmactical Manufacturing

Manufacturing gets no respect. Big pharmaceutical companies are easy targets of the media. Someone should do something to fix that.

These are some of the things I hear from pharmaceutical manufacturers every day. Many professionals believe that our industry gets a bad rap, and I think they’re right.

Our industry has created some of its own problems, of course, and must do more to, for example, ensure product quality and supply chain safety, improve manufacturing efficiency, and always put the patient first. If not, our image will continue to suffer in the eyes of the public.

But much of the criticism we face stems from the importance of the work we do. Our industry makes products that are life-changing, life-sustaining, and impact hundreds of millions of people worldwide. When the cost of a drug increases or there are problems with a new medication, the public feels the consequences. In these cases, it’s a natural reaction to search for someone or something upon which to assign blame. Often, it may appear to the public that pharmaceutical manufacturing professionals don’t take their responsibility to manufacture drugs safely and cost-effectively as seriously as I know they do.

The challenges facing pharmaceutical manufacturing have increased dramatically as well. Today’s pharmaceutical engineers and manufacturers face economic and regulatory pressures, accelerating costs, technology changes, and the need to constantly adapt their business models. The advent of biologics, more widely distributed supply chains, and many other influences demand greater investment; better integration of product, quality and manufacturing design; and greater industry collaboration overall. Quality controls, corrective and preventive actions (CAPAs) and root cause analyses that were once more straightforward are highly complex today, and the industry could benefit from agreement on how to use and apply technology to achieve greater gains in all areas, including quality and safety.

Collaboration between Industry and Regulators

Collaboration between Industry and Regulators

Organizations like ISPE work to address these very real issues every day. But we can do more. The industry must find ways to elevate our use of new technology and to sustain a dialogue between companies, technical experts, scientists and regulatory representatives that results in a shared approach to removing barriers to technology utilization and change. Relationships between industry, supply networks and regulatory agencies need to become more collaborative in the application of science and risk-based approaches for the development and manufacturing of new products.

Industry and regulatory leaders should openly discuss how to leverage new quality and manufacturing processes and how to capitalize on advancements in IT technology, such as cloud-based systems, to effectively manage data that will enhance productivity and quality. We need more dialogue about the use of advanced technologies—particularly those already proven successful in other industries—to enable improvements in production and transparency in more pharmaceutical companies.

When we hear other manufacturing industries discussing quality and data solutions that are driving decision-making, we need to be at the forefront as well, discussing how these new best practices can help advance the pharmaceutical manufacturing industry.

Our Responsibility

Our Responsibility

In an industry that faces huge levels of risk each day, change comes slowly—but it does come. Pharmaceutical manufacturers perform extraordinarily complex research, sophisticated testing, and compliance work.

Consumers won’t ever know the complexities of our industry or how many organizations worldwide touch a single drug as it is developed, tested, validated, manufactured, distributed and delivered to them. They won’t know that tens of thousands of people are dedicated to meeting their expectations of an ongoing pipeline of new, better and less costly medicines and vaccines or that this development work has a price tag in the billions, involving highly complicated processes.

But they know when a new drug saves lives, prolongs life or lessens pain.

With great power comes great responsibility. The pharmaceutical manufacturing industry knows what challenges we face. We must now be ready and able to meet them.

Subscribe to:

Comments (Atom)

-

Qualification:- B.Pharmacy , M.Pharma. Role & Responsibilities:- Draft quality assurance policies and proc...

-

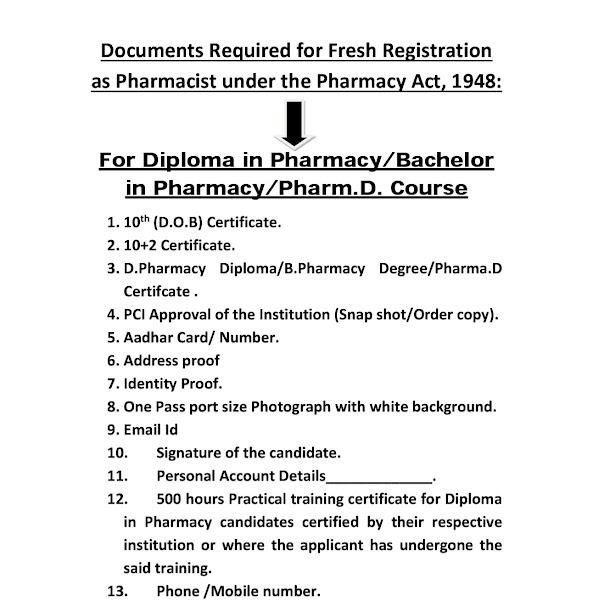

New Registration for B.Pharmacy (Submit original Certificates for verification/stamping) 1. Read General Procedure befor...

-

Chromatography Chromatography is usually introduced as a technique for separating and/or identifying the components in a mixture. The ...